Veteran owned for more than 40 years

Monday–Sunday, 24/7 | (888) 272-9044

Lockwood Products delivers proven boiler room solutions that enhance safety, reduce thermal stress, and help facilities meet code requirements. Designed for commercial and industrial boiler systems, Lockwood blowdown separators and feedwater equipment provide dependable performance in demanding environments.

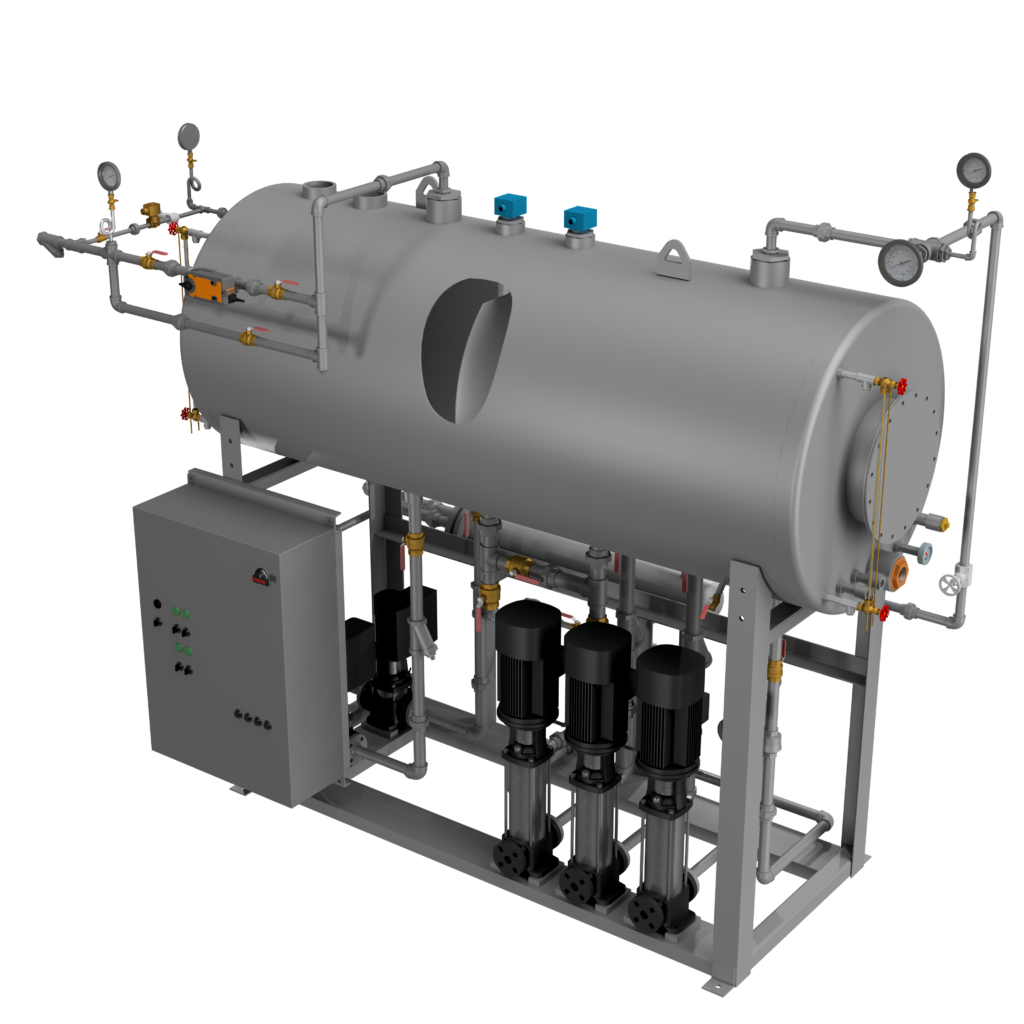

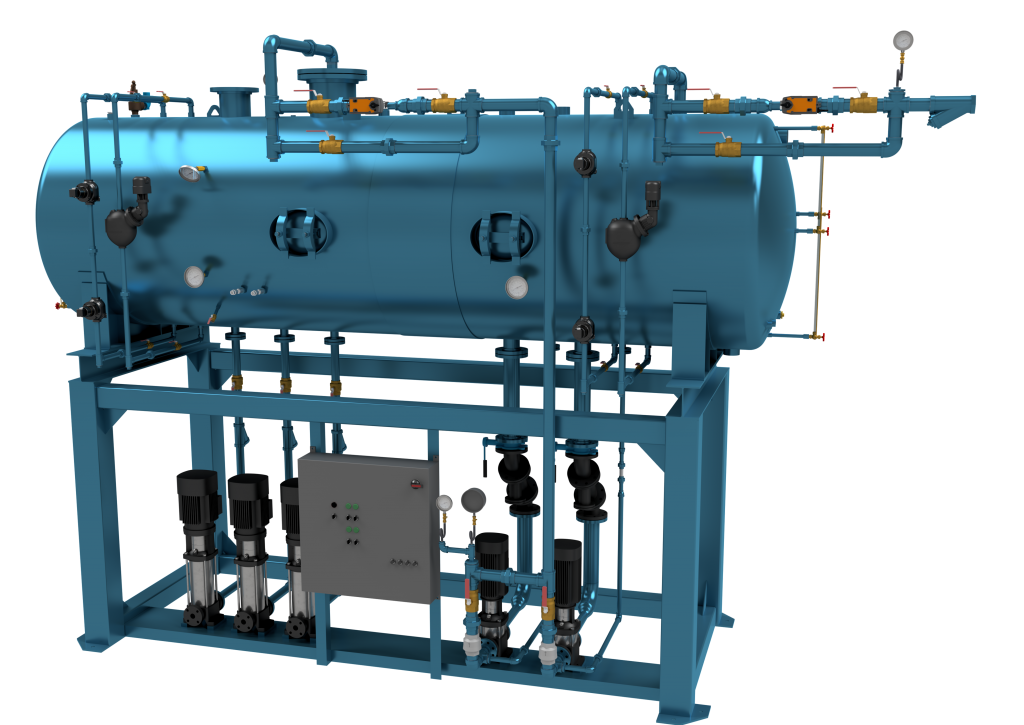

Lockwood horizontal boiler feed systems provide reliable feedwater delivery in boiler rooms with limited vertical space. They combine a horizontal feedwater tank with pumps and controls to supply one or more boilers consistently. This design is ideal for commercial and industrial facilities that need dependable performance and easy maintenance access.

These systems help maintain stable feedwater temperature and volume. As a result, they reduce pump cycling, improve boiler level control, and minimize thermal stress on boiler components. The heavy-duty steel tank and configurable pumps ensure long service life and flexibility.

Additionally, horizontal feed systems integrate seamlessly with firetube and watertube boilers, automatic feedwater controls, and chemical treatment programs. They are built to meet code requirements, making them a reliable choice for both new installations and retrofit projects.

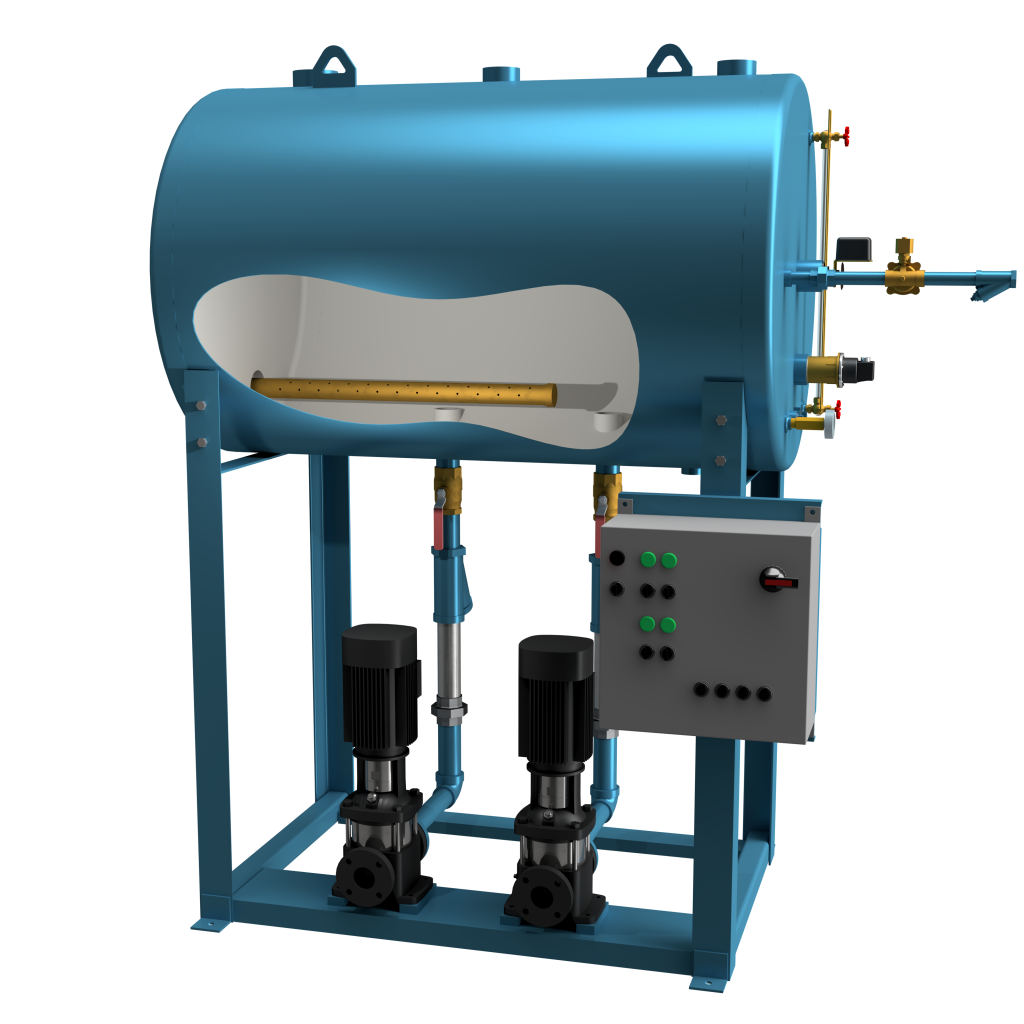

Lockwood vertical boiler feed systems are designed to save floor space while delivering reliable feedwater to one or more boilers. By stacking the feedwater tank and pump vertically, these systems minimize their footprint, making them ideal for commercial and industrial facilities with limited space.

Vertical feed systems maintain consistent feedwater temperature and volume. This helps stabilize boiler operation, reduce pump cycling, and protect piping from thermal stress. Their design also allows for clear piping layouts and easy access to pumps and controls for maintenance.

Furthermore, vertical systems integrate easily with firetube and watertube boilers, automatic feedwater controls, condensate return lines, and chemical treatment equipment. With durable steel construction and code-compliant design, these systems offer dependable performance for both new and retrofit applications.

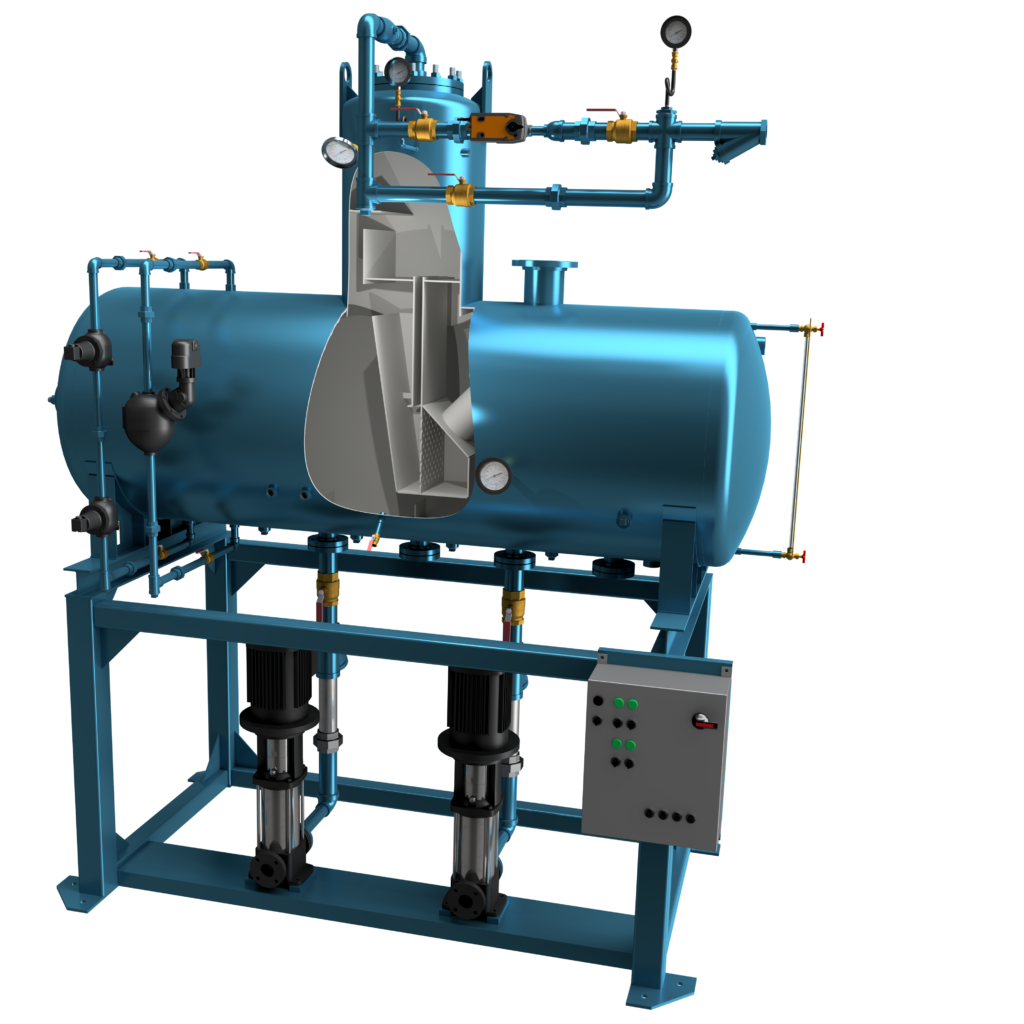

The Lockwood Type S.S. deaerator removes dissolved oxygen and other gases from boiler feedwater. This protects boilers, piping, and heat exchangers from corrosion. By heating makeup and return water to near-saturation temperatures, it improves water quality and ensures reliable boiler operation.

Additionally, the Type S.S. integrates easily with feedwater systems, condensate return lines, and chemical treatment programs. Its proven design reduces oxygen-related corrosion. Overall, it supports code-compliant operation and long-term system reliability.

The Lockwood Type SSL deaerator is built for high-capacity boiler plants. It efficiently removes dissolved oxygen and non-condensable gases while delivering near-saturation feedwater. This helps protect boilers, piping, and heat exchangers from corrosion and thermal stress.

Furthermore, the SSL integrates seamlessly with feedwater systems, condensate return lines, and chemical treatment programs. Its durable construction ensures long-term performance. For facilities needing large-capacity, code-compliant deaeration, the SSL is an ideal choice.

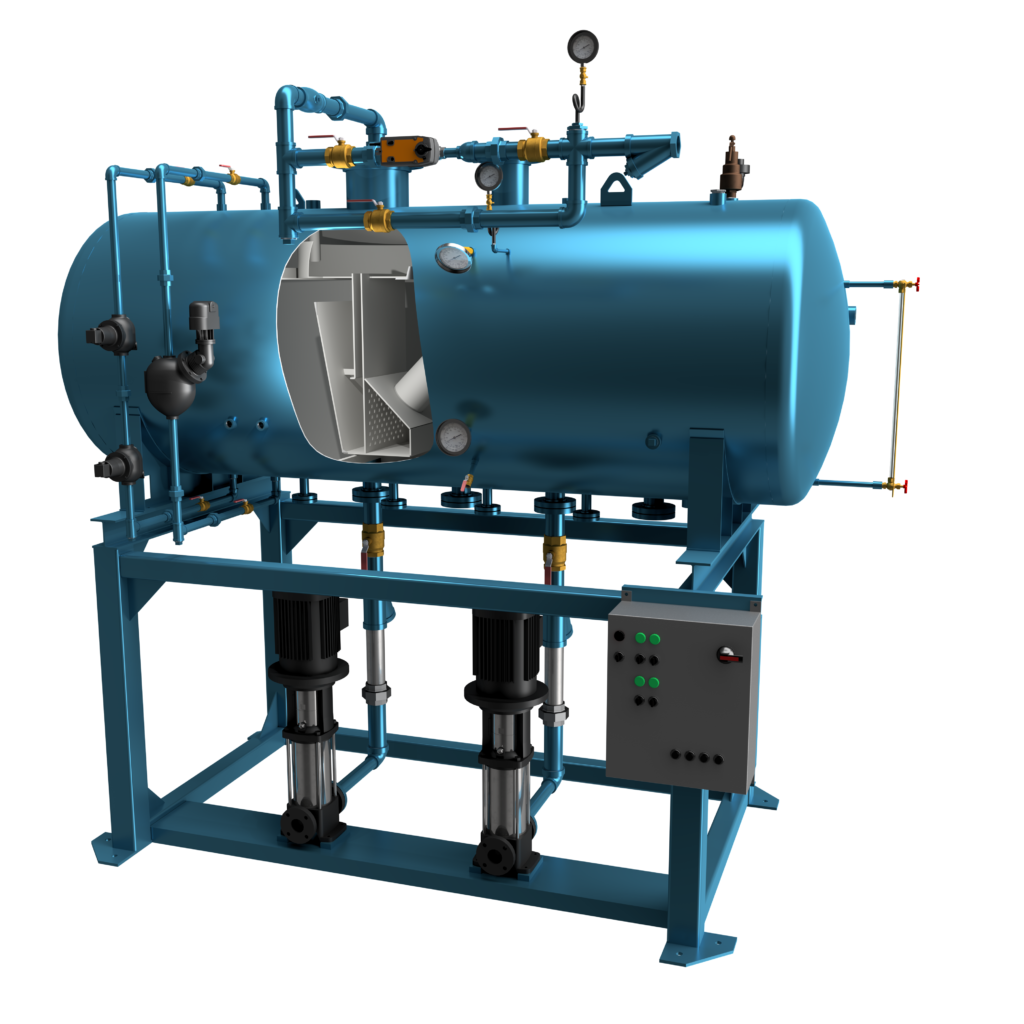

The Lockwood Type SSLDT deaerator is a dual-tank system for large boiler plants. It removes dissolved oxygen and other gases while storing heated feedwater. This design protects boilers, piping, and heat exchangers from corrosion and thermal stress.

Moreover, the dual-tank setup allows continuous operation during high-demand periods. The SSLDT integrates with feedwater systems, condensate returns, and chemical treatment programs. For facilities requiring high-capacity deaeration with built-in storage, it offers a reliable, code-compliant solution.

The Lockwood Type ST deaerator is a compact, space-saving solution. It removes dissolved oxygen and non-condensable gases from feedwater. This protects boilers, piping, and heat exchangers while maintaining stable boiler operation.

In addition, the Type ST works well with feedwater systems and condensate return lines. Its simple, durable design makes it ideal for facilities with limited space that still require reliable, code-compliant deaeration.

The Lockwood Type AD deaerator is a high-efficiency unit designed for commercial and industrial boilers. It removes dissolved oxygen and other gases, helping prevent corrosion and support stable boiler operation.

Also, the Type AD integrates smoothly with feedwater systems, condensate returns, and chemical treatment programs. Its robust design ensures long-term performance. For new or retrofit projects, the AD provides a reliable, code-compliant solution.